24V DRIVEN MOTOR ROLLERS

In 2015, NDW commenced the development of conveyor roller solutions which ensure that motorised roles can more easily be deployed and that a total transport installation can be controlled in a cheaper and more straight forward manner.

NDW’s drive rollers are the result of over two years of development. This innovation gives you complete control of your conveyor tracks and conveyor systems in terms of efficiency, durability and, of course, logistic deployment.

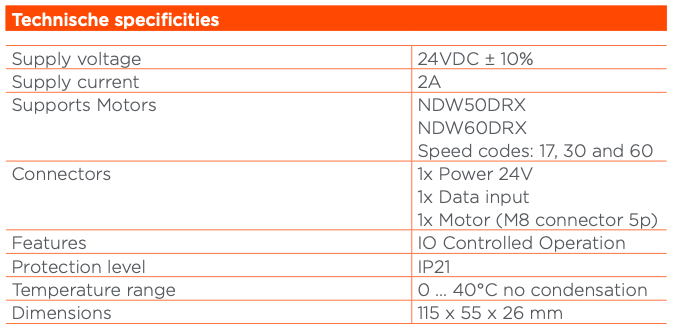

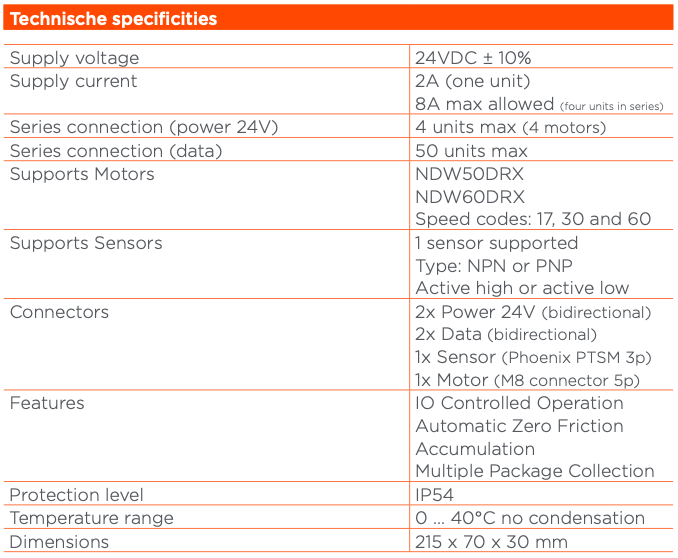

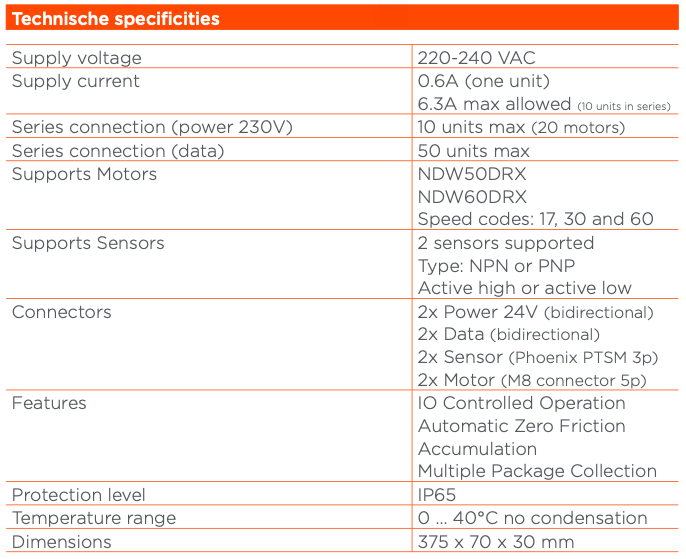

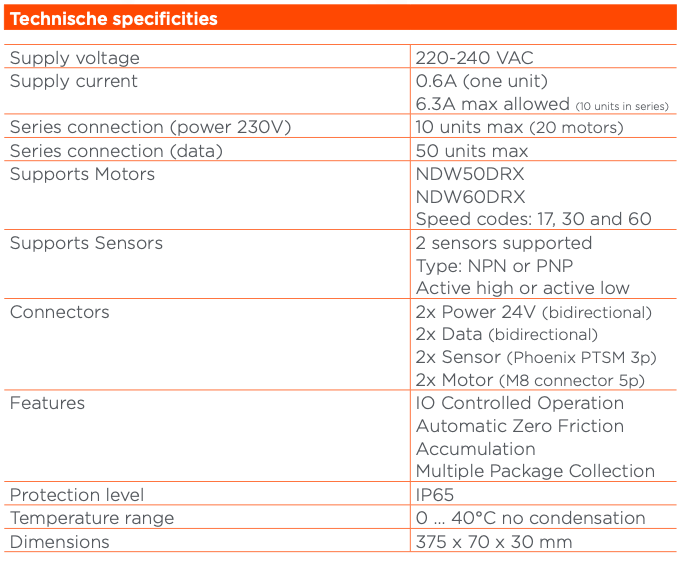

The result is that NDW is set to bring the first 4 drive controllers onto the market in 2018. These products are entitled: budget, basic, basic+24V and basic+230V, and can be used for standard transport installations as well as to control more complex installations. Thanks to the combination of a strong brushless conveyor roller (the 50DRX and 60DRX), NDW has a new technology and power that is suitable for transporting light to semi-heavy products, up to 300 kg.

The drive rollers are driven by the NDW Controllers, which are available in four versions, ranging from straightforward controllers for each drive roller to controllers that communicate with each, so you can set up your belt for optimal efficiency. Naturally, we work constantly to improve and extend those controllers. The drives in the rollers themselves are the products of far-reaching research and continued development. In fact, we’re not afraid to say that NDW supplies powerful drive rollers with long-lasting quality.

NDW’s drive rollers are the result of over two years of development. This innovation gives you complete control of your conveyor tracks and conveyor systems in terms of efficiency, durability and, of course, logistic deployment.

The result is that NDW is set to bring the first 4 drive controllers onto the market in 2018. These products are entitled: budget, basic, basic+24V and basic+230V, and can be used for standard transport installations as well as to control more complex installations. Thanks to the combination of a strong brushless conveyor roller (the 50DRX and 60DRX), NDW has a new technology and power that is suitable for transporting light to semi-heavy products, up to 300 kg.

The drive rollers are driven by the NDW Controllers, which are available in four versions, ranging from straightforward controllers for each drive roller to controllers that communicate with each, so you can set up your belt for optimal efficiency. Naturally, we work constantly to improve and extend those controllers. The drives in the rollers themselves are the products of far-reaching research and continued development. In fact, we’re not afraid to say that NDW supplies powerful drive rollers with long-lasting quality.

NDW offers new possibilities in the area of controlling transport installations. Our products are ideal for plug-and-play solutions and have the option of communicating with each other. A major benefit is therefore that we can use an integrated power supply. This removes the need for a transformer and we can accumulate and combine without PLC. Another major advantage is that our controllers can be programmed remotely with the exclusive NDW Connect solution. Our solutions are also perfect for the food industry thanks to the IP65 controllers and because we no longer require a power converter.

The NDW DRX conveyor rollers are built for different applications. The conveyor roller is therefore available in both galvanised steel and stainless steel and in the ø50mm and ø60 mm diameters. The protection index is IP 54 and IP 65. The motors are supplied in 3 different speed codes: 17, 30 and 60. The conveyor rollers can also be equipped with a rubber, PU or PVC lining and the conveyor rollers are equipped with conic components for curved applications.

KEY FEATURES

Plug and Play:

Pre-programmed settings for simple installation and testing

Wireless Control:

Adjust settings remotely and update the firmware versions via the cloud. All applications are available via the cloud.

NDW Connect:

NDW Connect is a smart technology which places internal transportation systems in the cloud, making global support, service and monitoring available and affordable for everyone.

Monitoring and Service:

Built-in flash for service applications and malfunctions logbook

Remote global support

Point to point communication for easy expansion:

Every basic and basic+ controller can communicate with the controller to its left and right. This easily makes it possible to expand the system in an accumulating way and it is possible to integrate more complex tasks. Consider triggering the pneumatics or

the application of movement controlled sensors

Plug and Play:

Pre-programmed settings for simple installation and testing

Wireless Control:

Adjust settings remotely and update the firmware versions via the cloud. All applications are available via the cloud.

NDW Connect:

NDW Connect is a smart technology which places internal transportation systems in the cloud, making global support, service and monitoring available and affordable for everyone.

Monitoring and Service:

Built-in flash for service applications and malfunctions logbook

Remote global support

Point to point communication for easy expansion:

Every basic and basic+ controller can communicate with the controller to its left and right. This easily makes it possible to expand the system in an accumulating way and it is possible to integrate more complex tasks. Consider triggering the pneumatics or

the application of movement controlled sensors