Powered Rollers

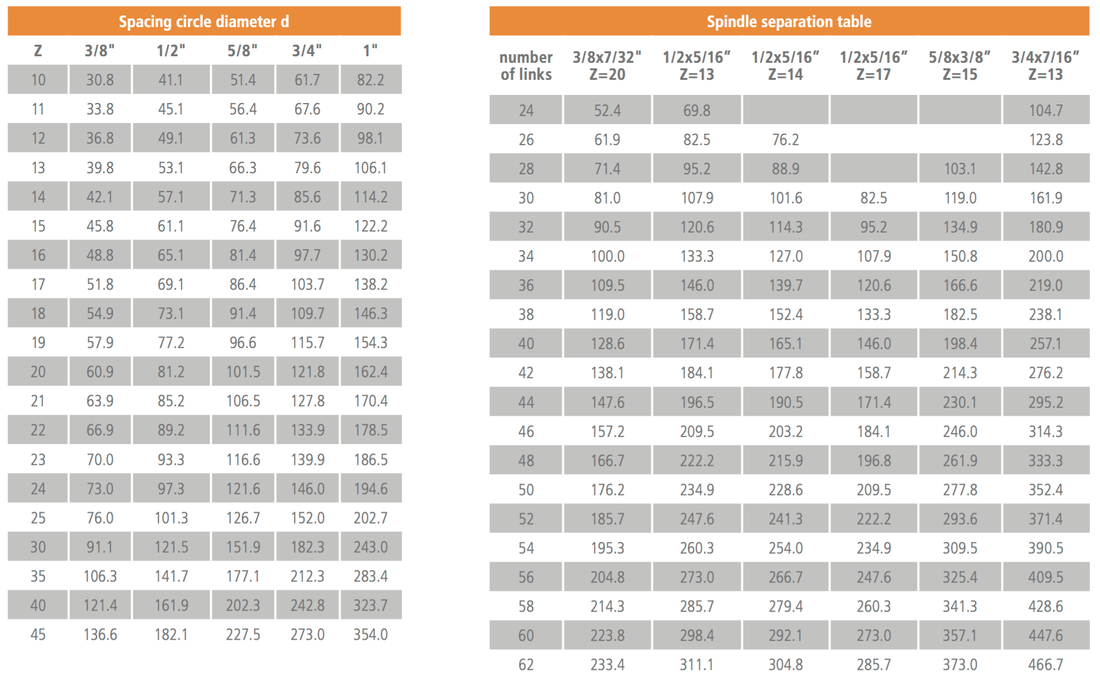

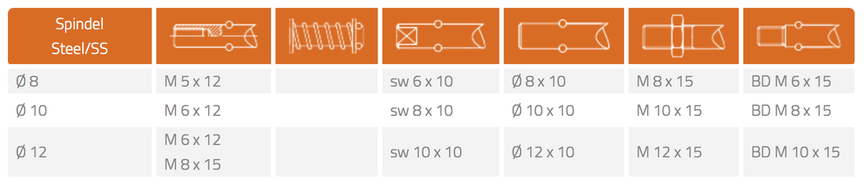

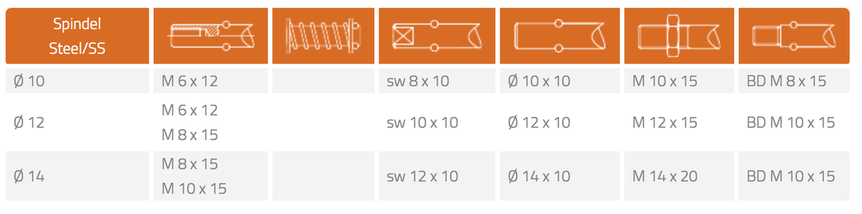

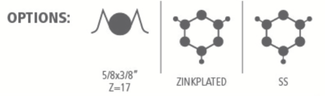

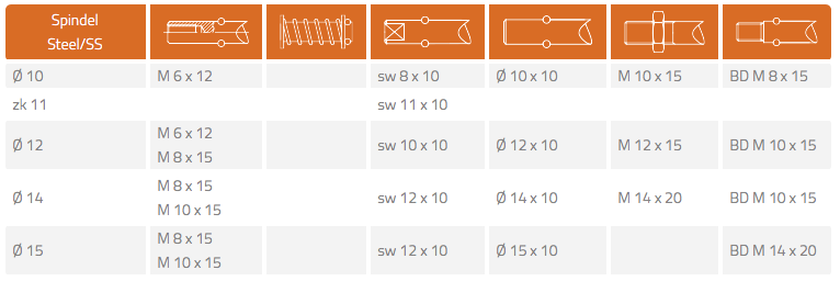

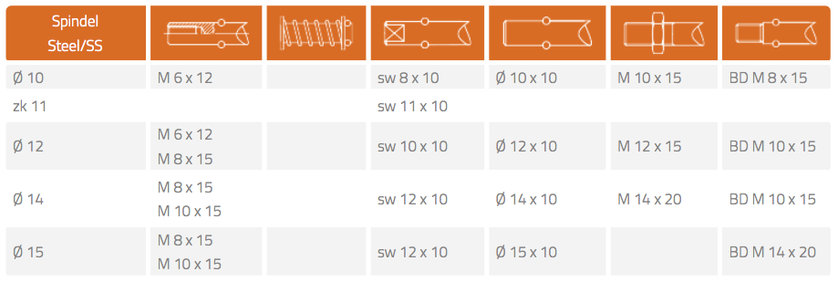

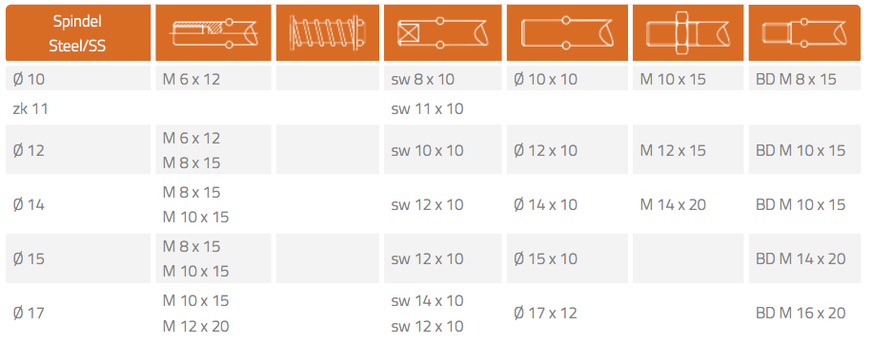

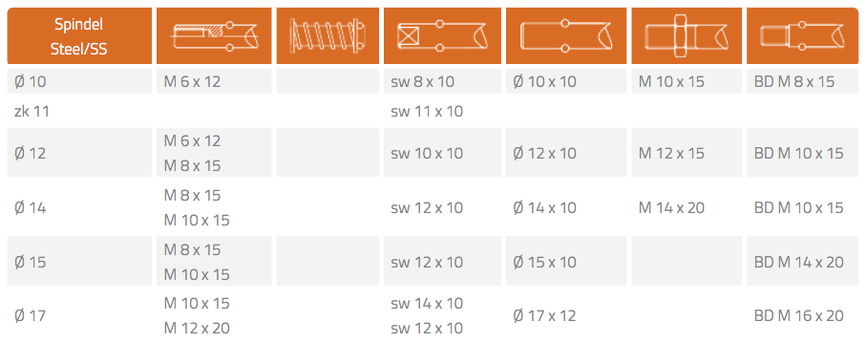

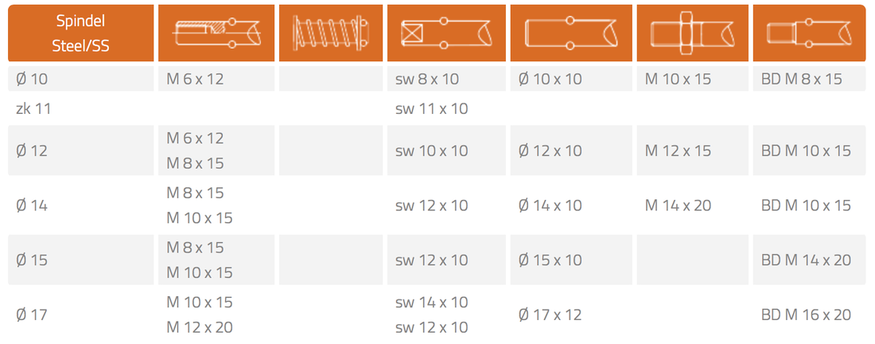

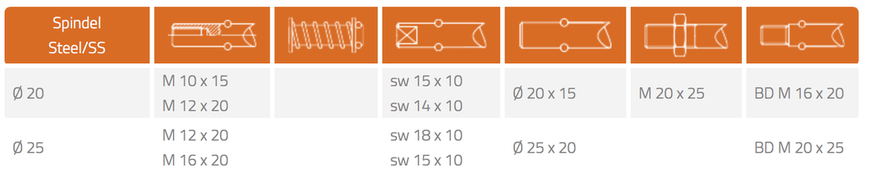

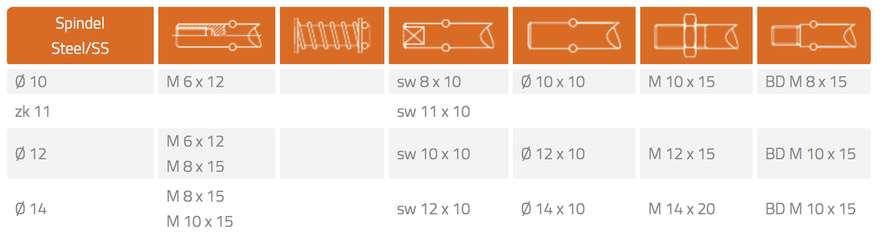

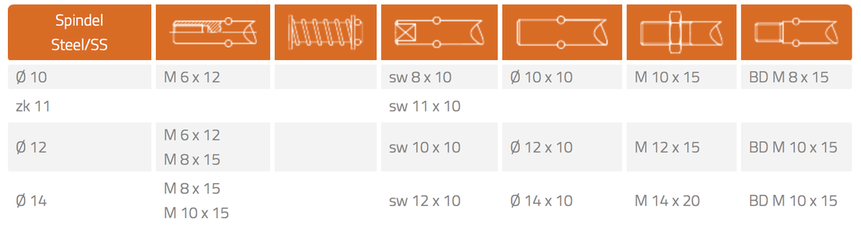

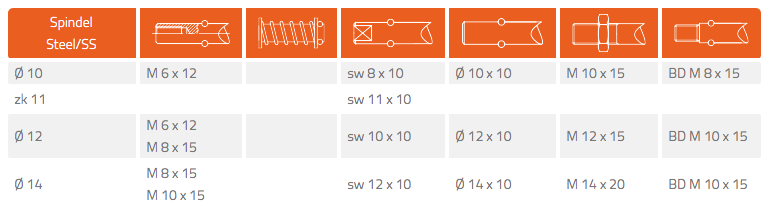

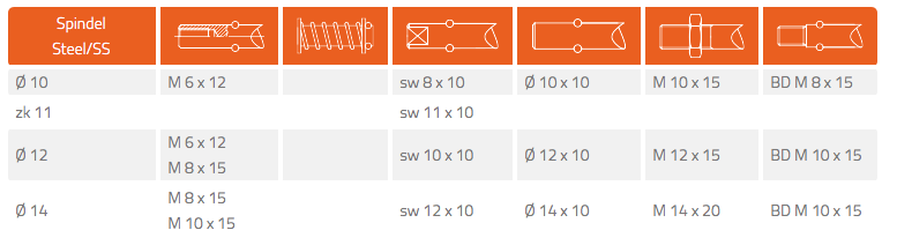

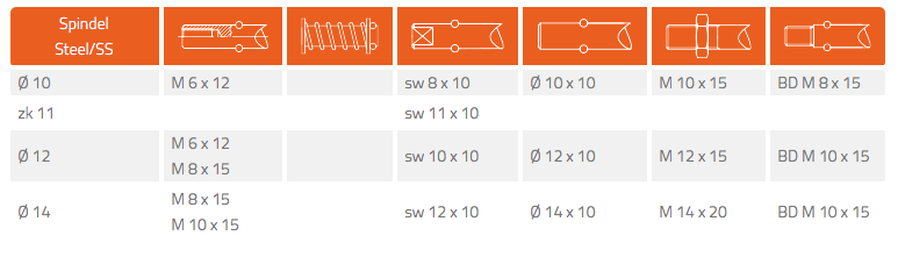

In the table you can find information about the dimensions of chain and sprockets, the advantages and disadvantages of a powered conveyor suited with a single row or double row sprocket. Also you'll find some points of attention for using accumulating conveyor rollers.

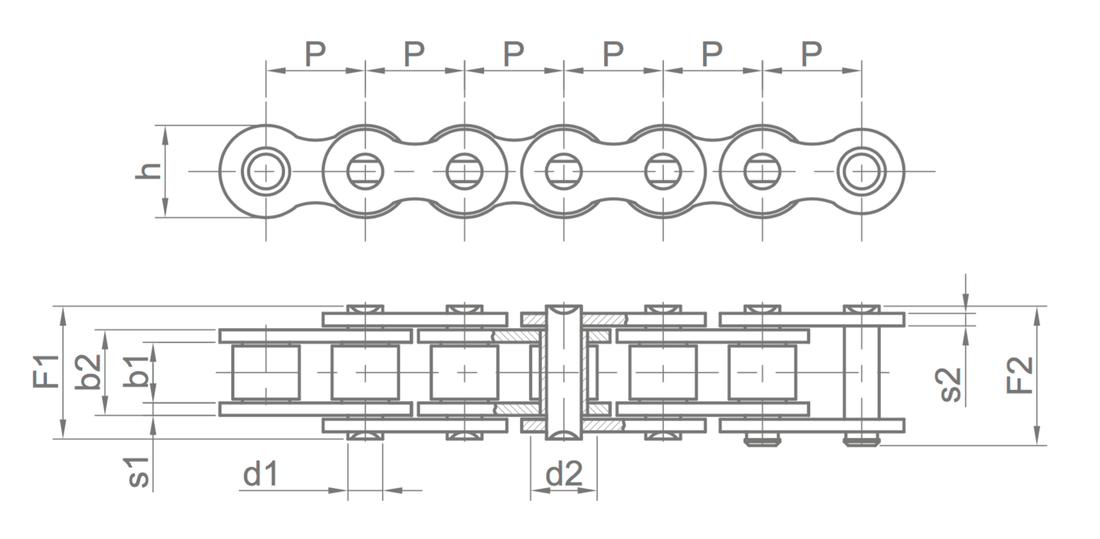

Chains

Chains

- a chain must not be under tension higher than 10% of its breaking strain. The maximum is 7% for an impact tension

- in the case of chain powered transport rollers, resistance due to chain and roller together comprise 10% of the load on the roller

- the points above combine to give the following rule of thumb; the total weight on a conveyor segment must not exceed the breaking strain of the chain

- the chain should be in contact with at least 90' of the driving wheel

- when there is an odd number of links in the chain, an offset section should be included

|

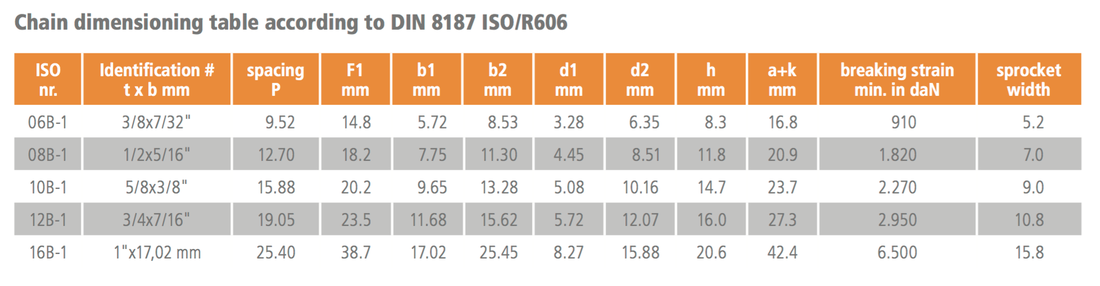

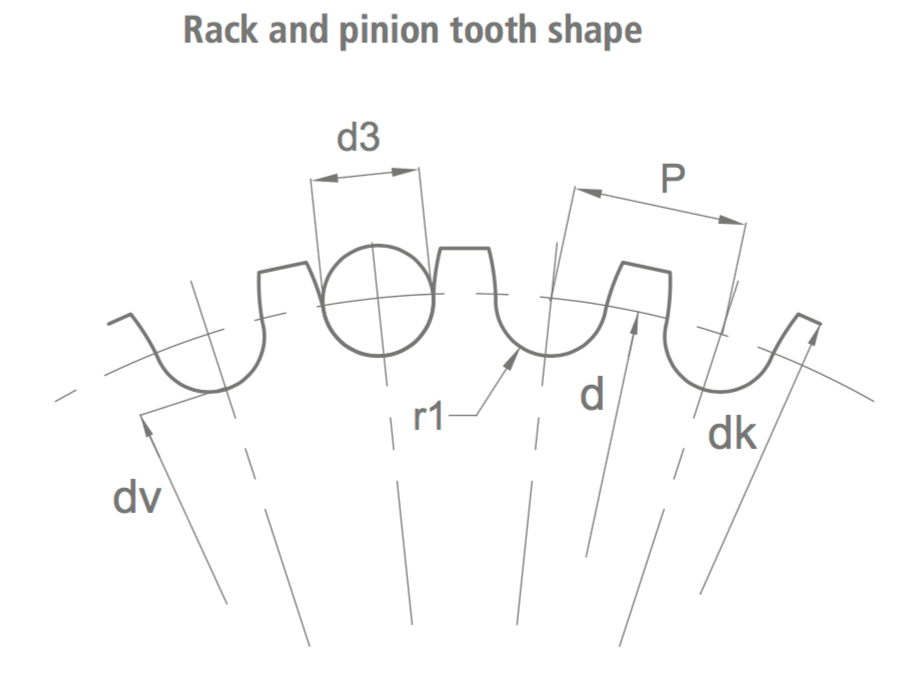

When a sprocket has a span arch of more than 90', the standard tooth shape can be used. When the span arch is less than 90' of the sprocket, a rack and pinion tooth shape (triebstock) can be used. The advantages of this are; broader and stronger teeth, less wear (due to the lesser extent to which the chain is pushed out of the tooth sockets) and quieter running.

|

P =pitch

Z =number of teeth d =pitch diameter : P / sin x 180 / Z dk =outer diameter : d + 0.90 x d1 dv =root diameter : d - 1.01 x d1 H-H =axels when Z1 = Z2 : 1/2 x (number of links- Z) x P |

When using accumulating load rollers

- the time a product takes to be conveyed is variable

- the pressure accumulation is 5% to &% of the conveyor load

- the pressure accumulation is reduced by 1% for every 1% upward gradient of the conveyor

- the pressure accumulation is increased by 1% for every 1% downward gradient of the conveyor

- the product ,just not bump up against the side guides

- the product must have a hard and flat underside

- the product is placed above the friction coupling a much as possible

- there is less wear of chain and sprockets because the torque due to drag is evenly spread

- the transport rate (V) may not be higher than 0.5 m/sec, at diameter 80mm

|

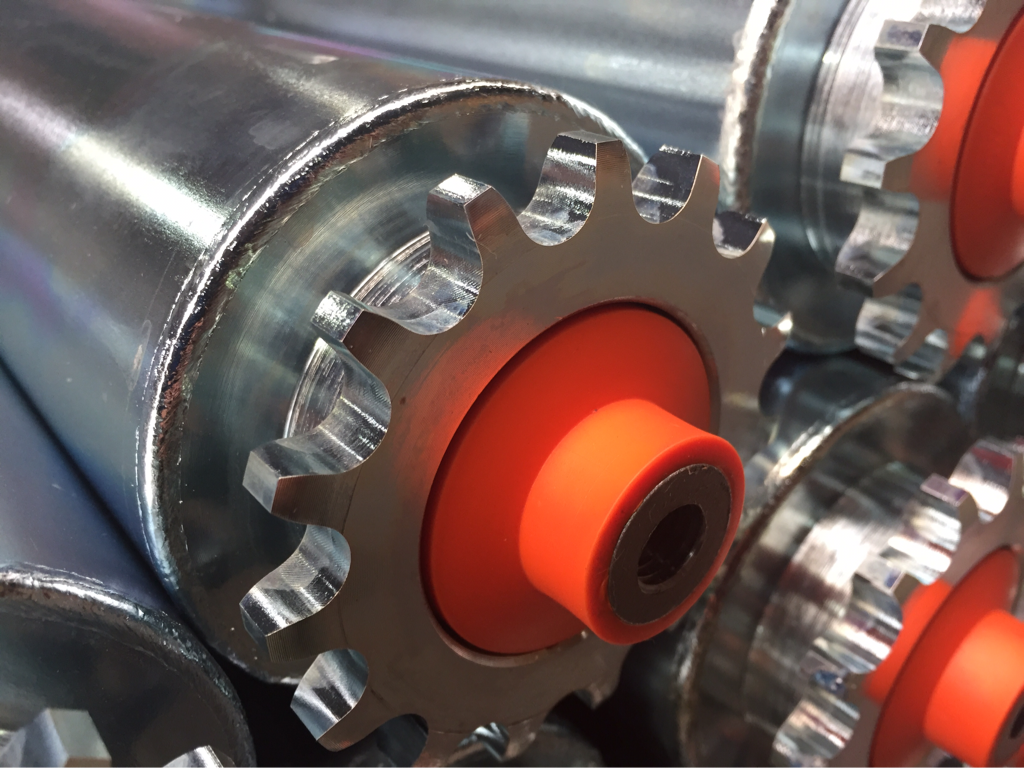

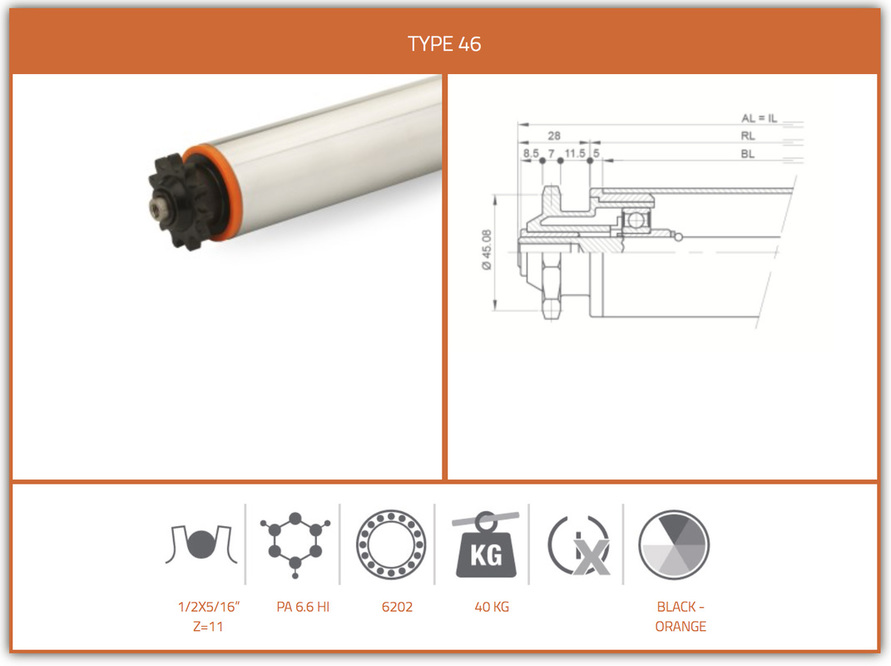

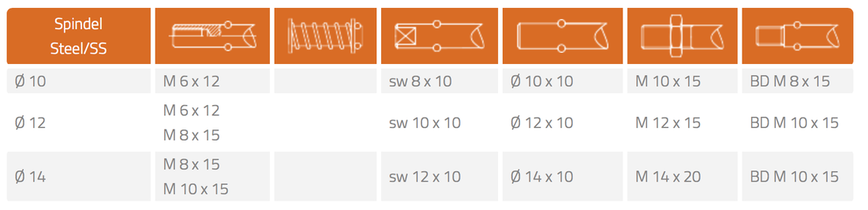

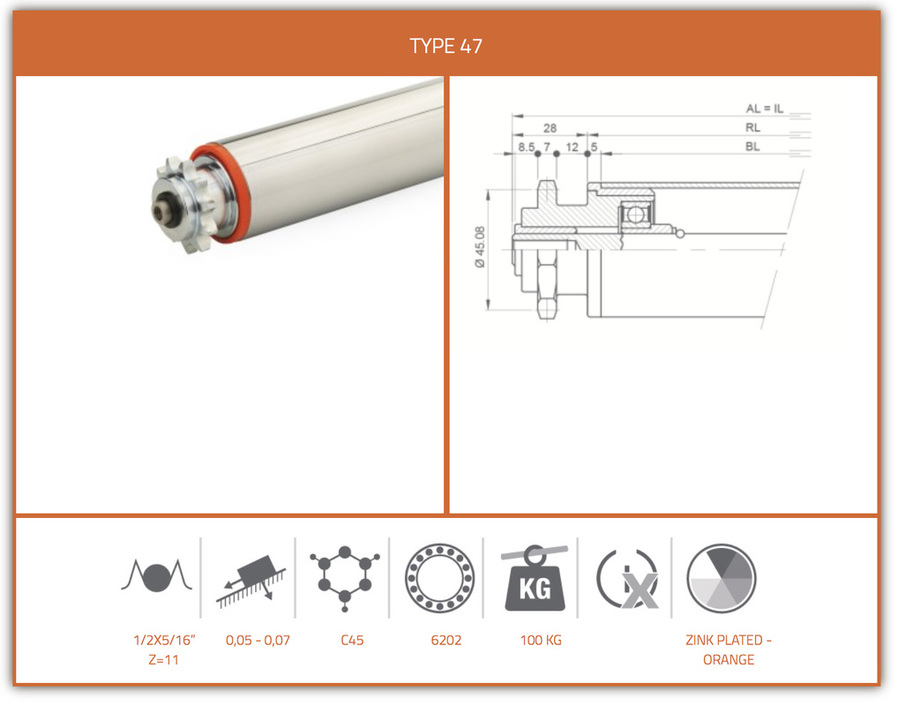

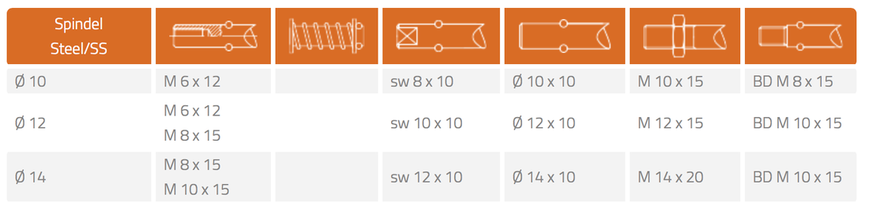

Type 47

Accumulating conveyor roller with a single steel sprocket, fitted with a grooved ball bearing. Because it makes use of a friction coupling, this roller is suitable for an accumulating roller conveyor for the transportation of medium-heavy products with hard and flat undersides. Also available with a fixed plastic ring exclusively for use in continuous transportation. |

|

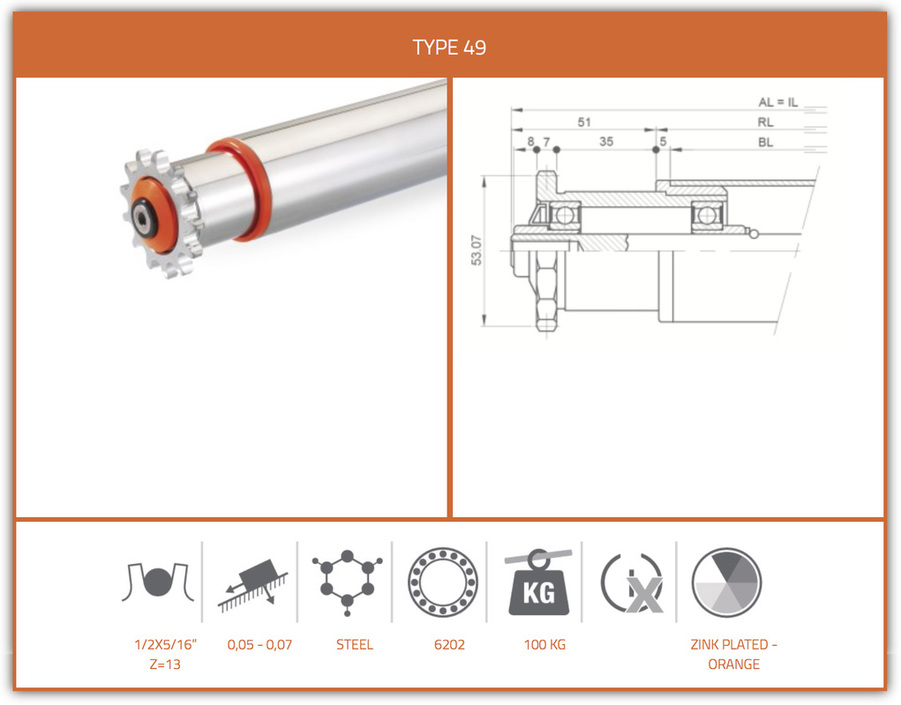

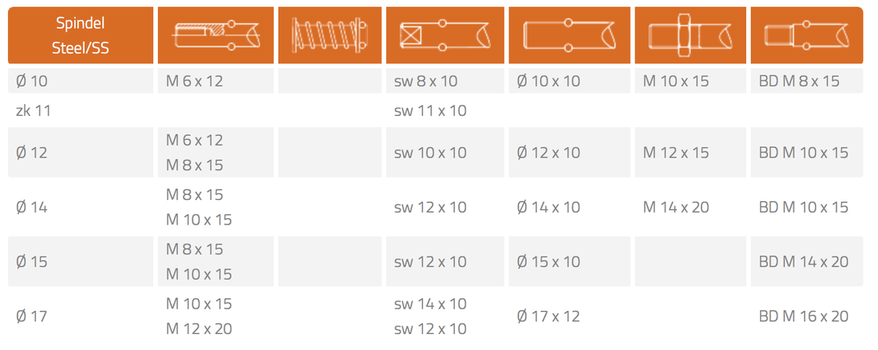

Type 49

Accumulating conveyor roller with a single steel sprocket, fitted with two grooved ball bearings. Because it makes use of a friction coupling, this roller is suitable for an accumulating roller conveyor for the transportation of medium-heavy products with a hard and flat underside. Also available with a fixed plastic ring exclusively for use in continuous transport. |

|

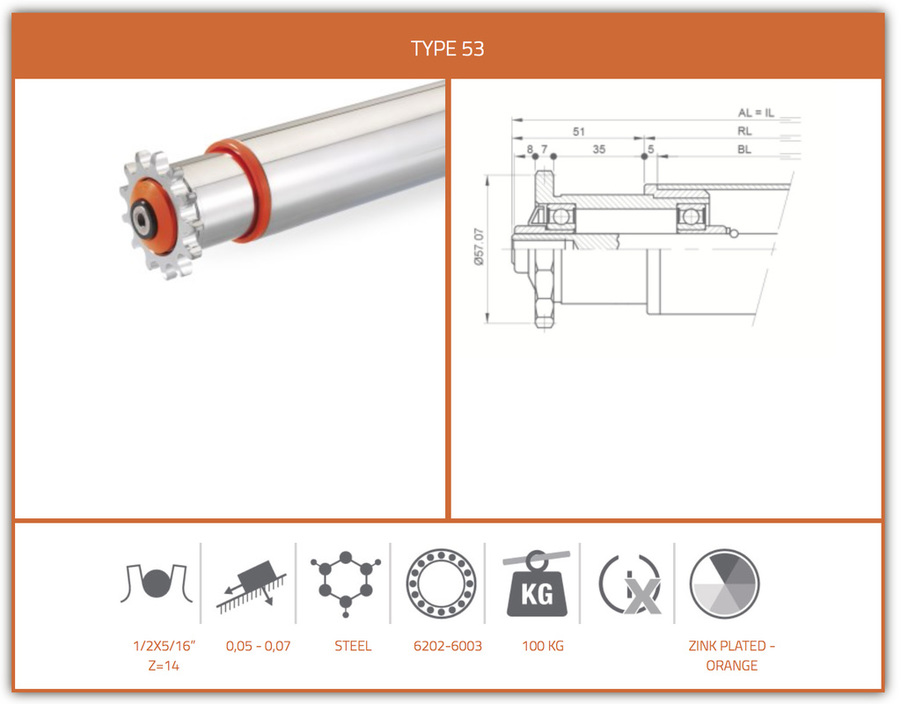

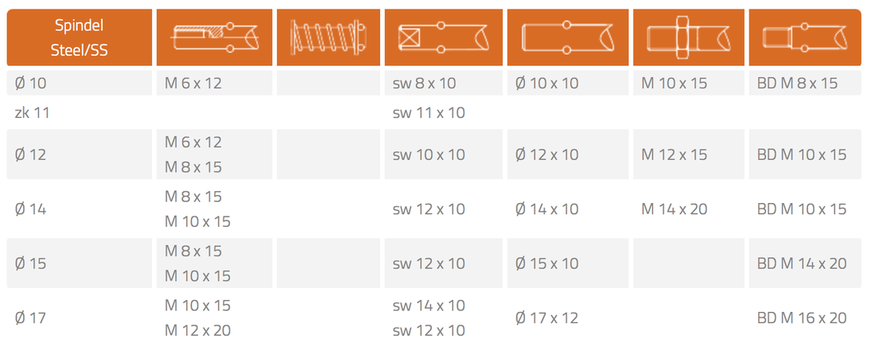

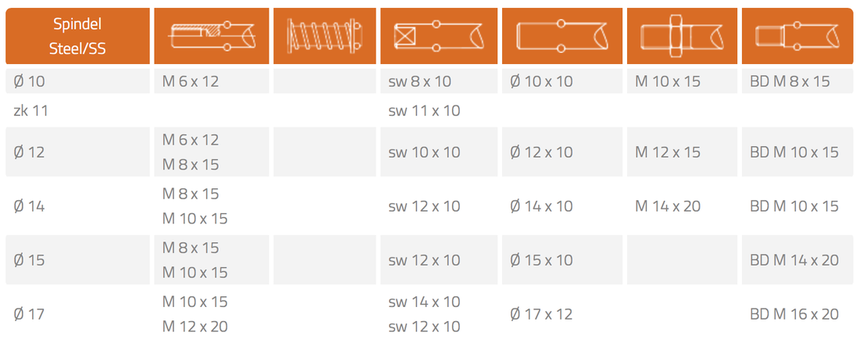

Type 53

Accumulating conveyor roller with a single steel sprocket, fitted with two grooved ball bearings. Because it makes use of a friction coupling, this version is suitable for an accumulating roller conveyor for the transportation of medium-heavy products with a hard and flat underside. Also available with a fixed plastic ring exclusively for use in continuous transport. |

|

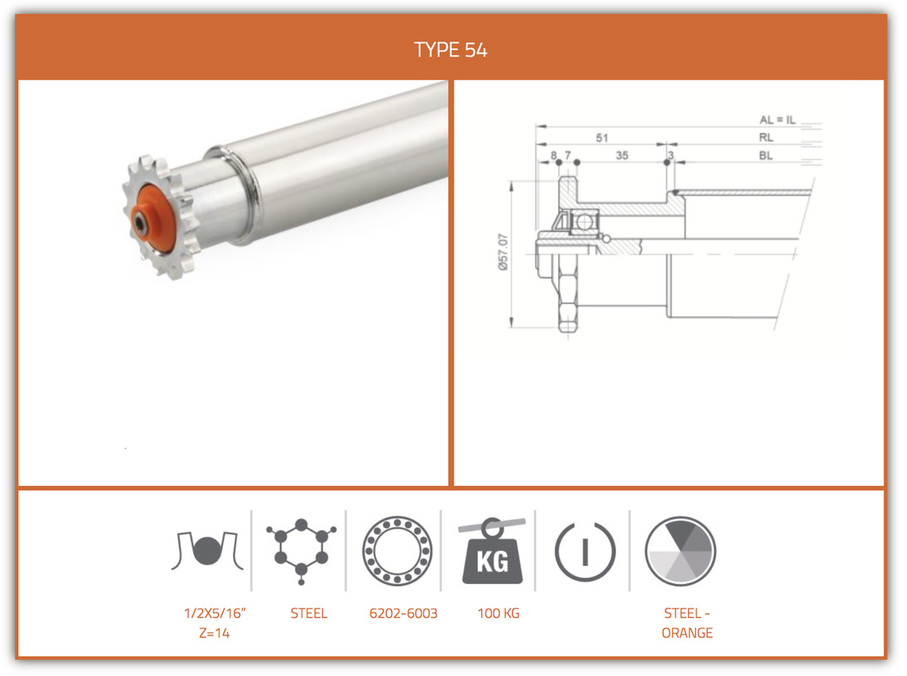

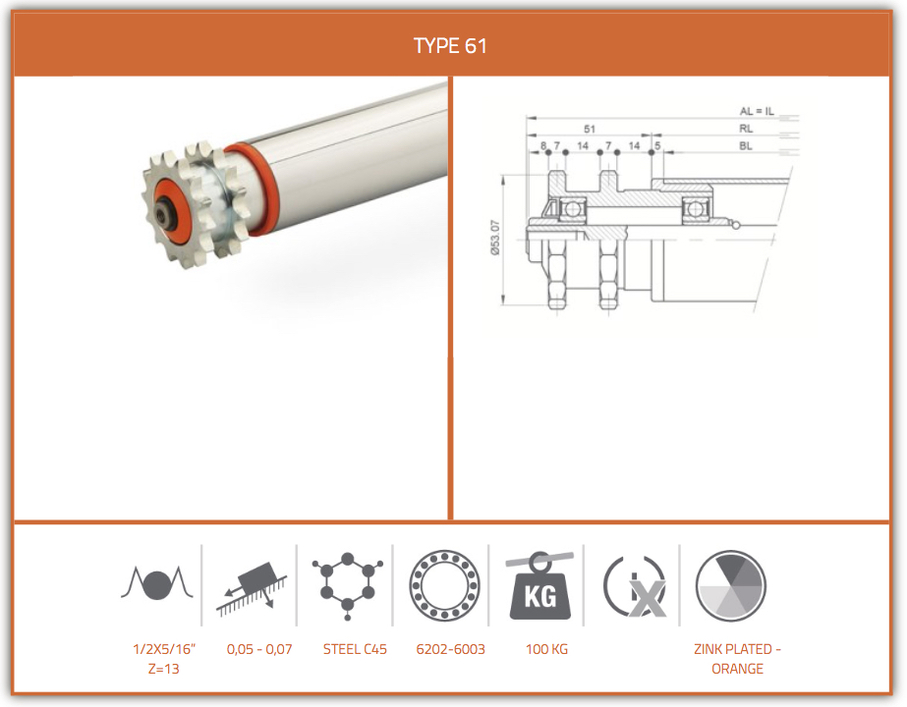

Type 61

Accumulating conveyor roller with a double steel sprocket, fitted with two grooved ball bearings. Because it makes use of a friction coupling, this version is suitable for an accumulating roller conveyor for the transportation of lightweight products with a hard and flat underside. Also available with a fixed plastic ring exclusively for use in continuous transport. |

|

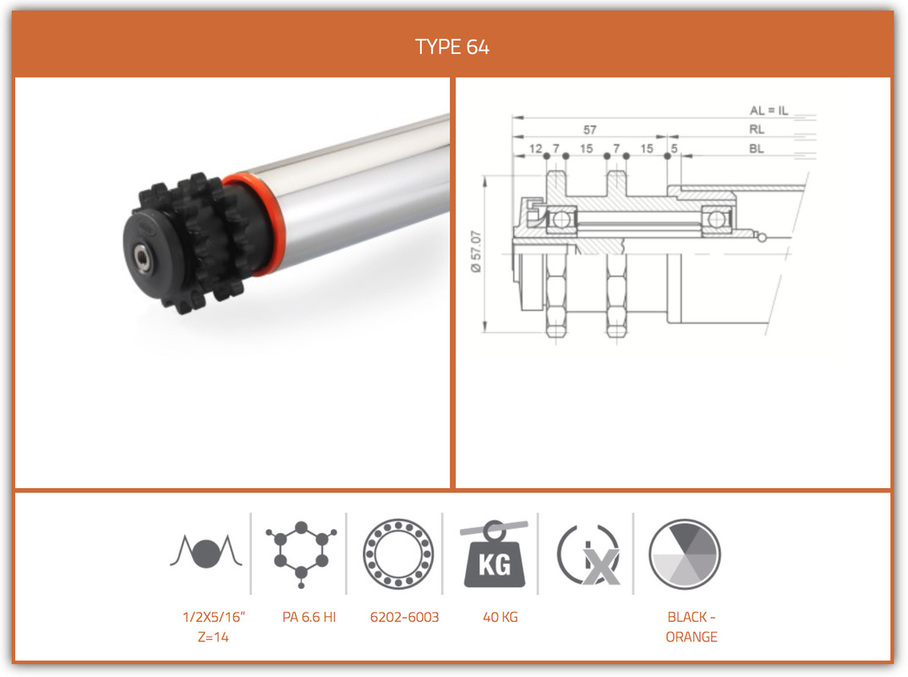

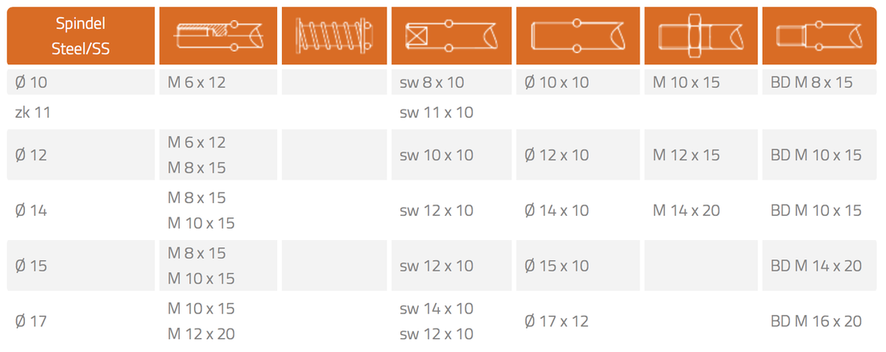

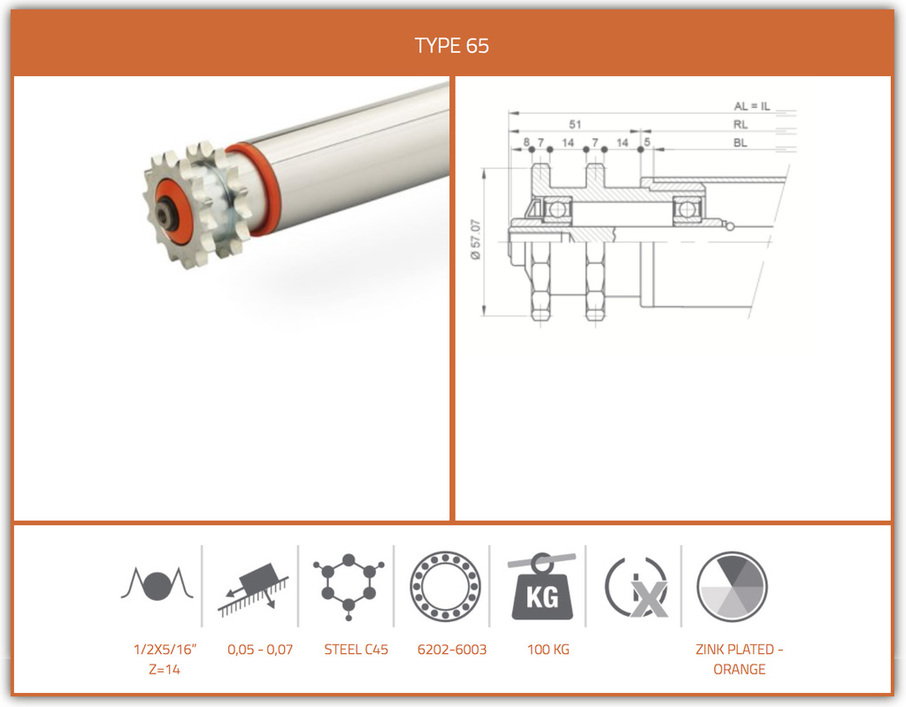

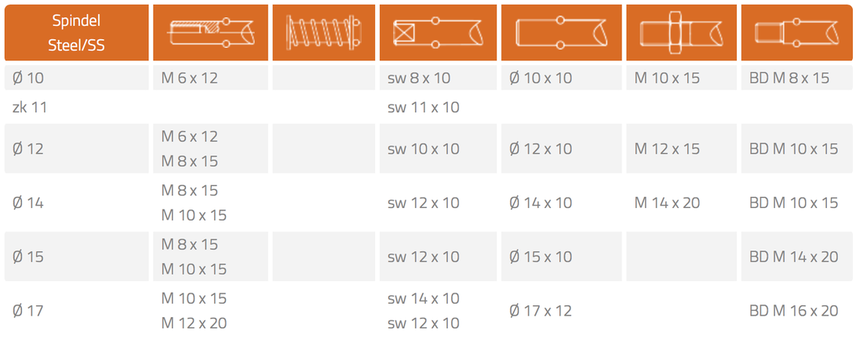

Type 65

Accumulating conveyor roller with a double steel sprocket, fitted with two grooved ball bearings. Because it makes use of a friction coupling, this version is suitable for an accumulating roller conveyor for the transportation of medium-heavy products with a hard flat underside. Also available with a fixed plastic ring exclusively for use in continuous transport. |

|

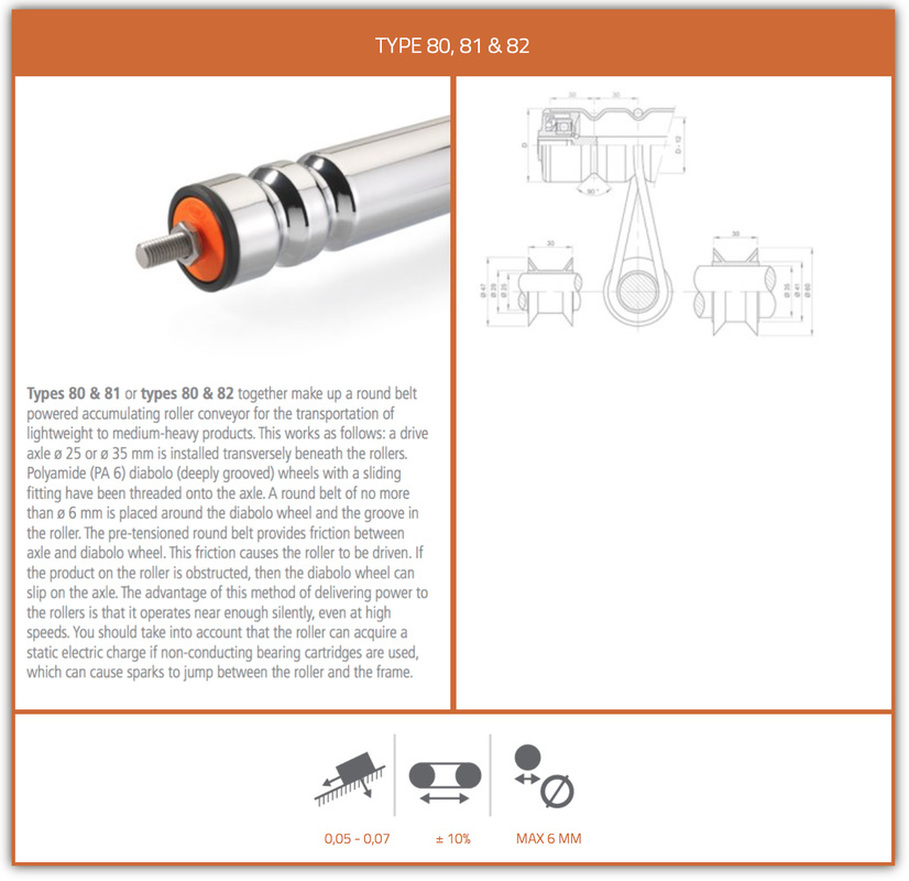

Type 80, 81 and 82

Types 80 & 81or 80 & 82 together make up a round belt powered accumulating roller for the transportation of lightweight to medium-heavy products. This works as follows: a drive axle 25 or 30 dia is installed transversely beneath the rollers. Polyamide (PA 6) diabolo (deeply grooved) wheels with a sliding fitting have been threaded onto the axle. A round belt of no more than 6mm dia is placed around the diabolo wheel and the groove in the roller. The pre-tensioned round belt provides friction between axle and diabolo wheel. This friction causes the roller to be driven. If the product on the roller is obstructed, then the diabolo wheel can slip on the axle. The advantage of this method of delivering power to rollers is that it operates nearly silently, even at high speeds. You should take into account that the roller can acquire a static electric charge if non-conducting bearing cartridges are used, which can cause sparks to jump between the roller and the frame. |

|

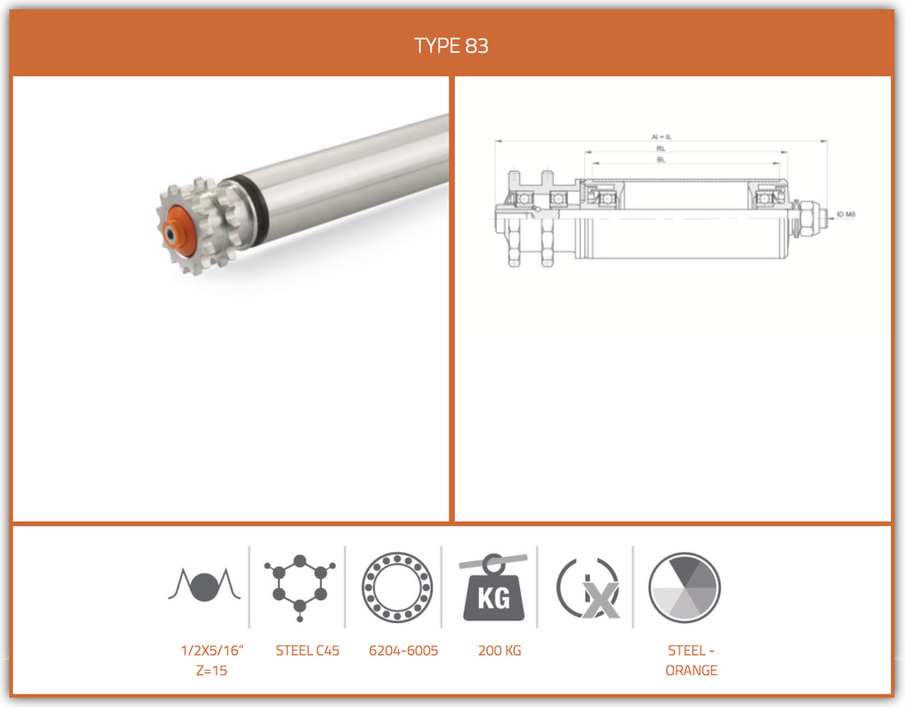

Type 83

Accumulating load roller with adjustable accumulation pressure. Can be implemented with a single or double steel sprocket head, fitted with grooved ball bearings. Suitable for transporting medium-heavy to heavy products that do not vary in weight. The friction from the dry plate coupling can be adjusted by means of a self-locking nut. |

|

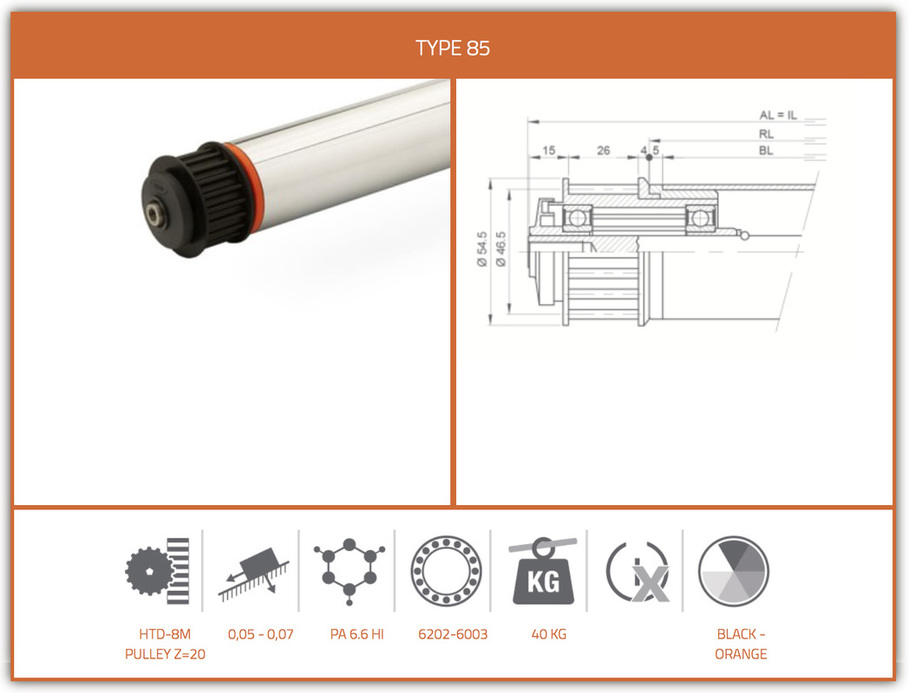

Type 85

Accumulating load roller with a plastic HTD-8M pulley for a tangential soothes belt, fitted with two grooved ball bearings. Because it uses a friction coupling, this version is suitable for an accumulating roller conveyor for low-noise transportation of lightweight products with a hard and flat underside. |

|

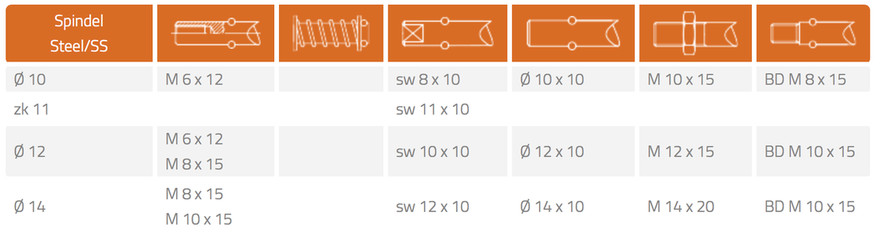

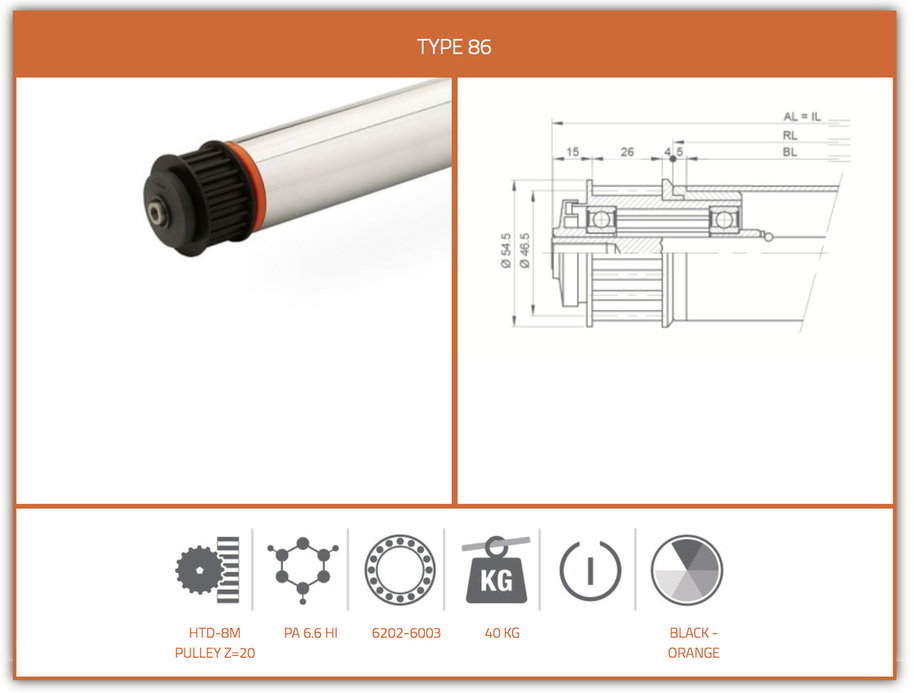

Type 86

Fixed powered load roller with a plastic HTD-8M pulley for a tangential toothed belt, fitted with two grooved ball bearings. Suitable for transporting lightweight products at a high transportation speed and a low noise level. This version is exclusively for the use in continuous transportation. |

|

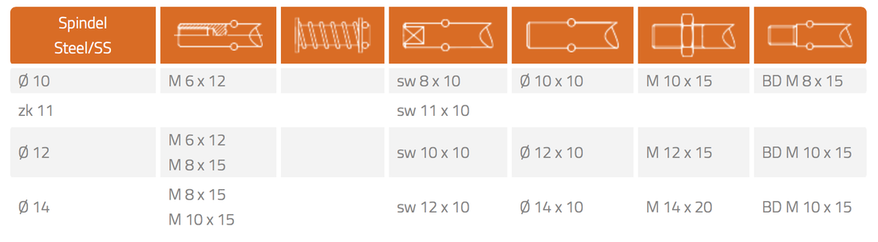

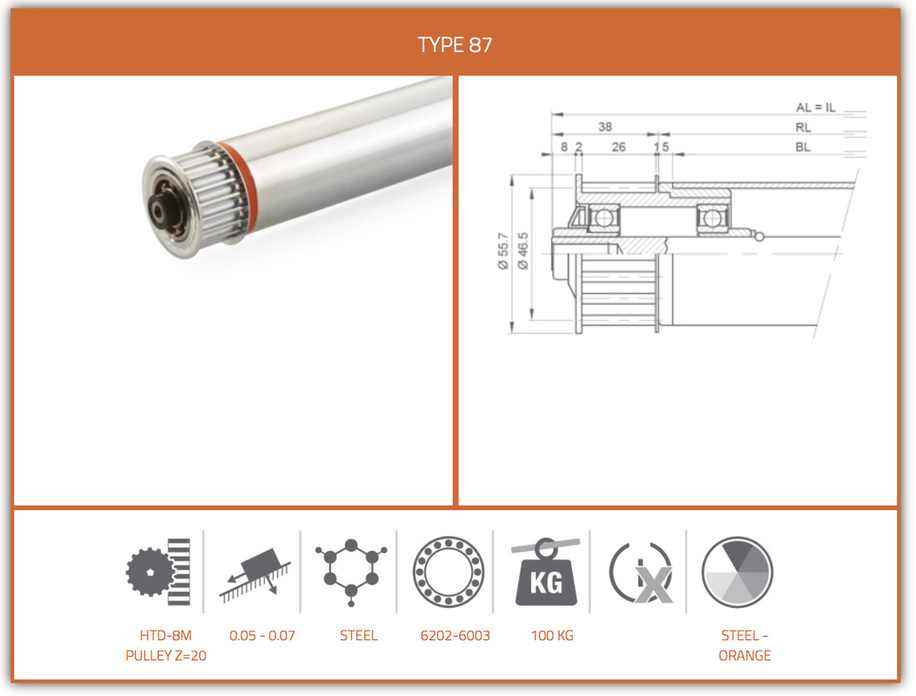

Type 87

Accumulating load roller with a steel HTD-8M pulley for a tangential toothed belt, fitted with two grooved ball bearings. Because it makes use of a friction coupling, this version is suitable for an accumulating roller conveyor for low-noise transportation of medium-heavy products with a hard and flat underside. |

|

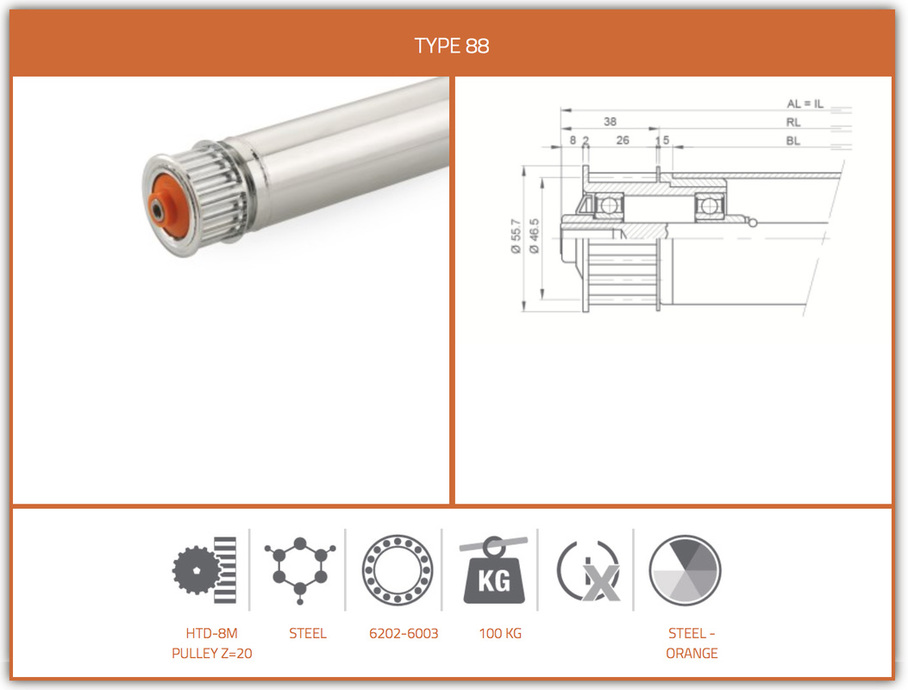

Type 88

Fixed powered load roller with a steel HTD-8M pulley for a tangential toothed belt, fitted with two grooved ball bearings. Suitable for transporting medium-heavy products at high transportation speed and a low noise level. this version is exclusively for use in continuous transportation applications. |

Type 89-1KA

Accumulating conveyor roller with a plastic Poly-VG head , fitted with two grooved ball bearings. Because it makes use of a friction coupling, this roller is suitable for an accumulating roller conveyor for the transportation of lightweight products with hard and flat undersides and is a low-noise conveyor- roller.

Accumulating conveyor roller with a plastic Poly-VG head , fitted with two grooved ball bearings. Because it makes use of a friction coupling, this roller is suitable for an accumulating roller conveyor for the transportation of lightweight products with hard and flat undersides and is a low-noise conveyor- roller.

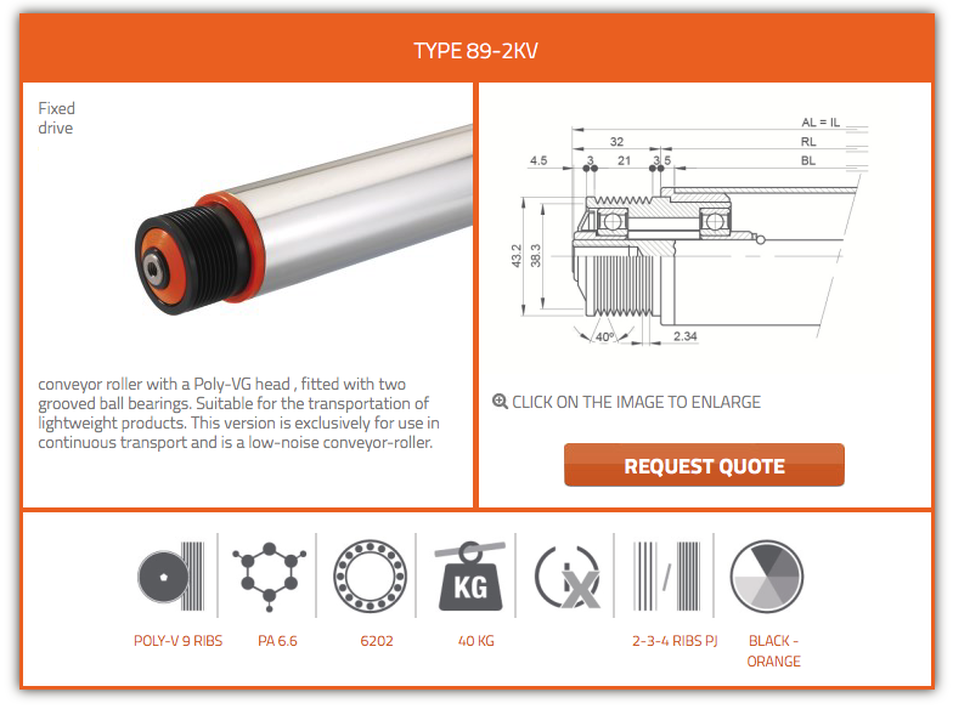

Type 89-2KV

Fixed drive conveyor roller with a Poly-VG head , fitted with two grooved ball bearings. Suitable for the transportation of lightweight products. This version is exclusively for use in continuous transport and is a low-noise conveyor-roller.

Fixed drive conveyor roller with a Poly-VG head , fitted with two grooved ball bearings. Suitable for the transportation of lightweight products. This version is exclusively for use in continuous transport and is a low-noise conveyor-roller.

Type 89-3SA

Accumulating drive conveyor roller with a Steel Poly-VG head, fitted with two grooved ball bearings. Suitable for the transportation of lightweight products. This version is exclusively for use in continuous transport and is a low-noise conveyor-roller

Accumulating drive conveyor roller with a Steel Poly-VG head, fitted with two grooved ball bearings. Suitable for the transportation of lightweight products. This version is exclusively for use in continuous transport and is a low-noise conveyor-roller

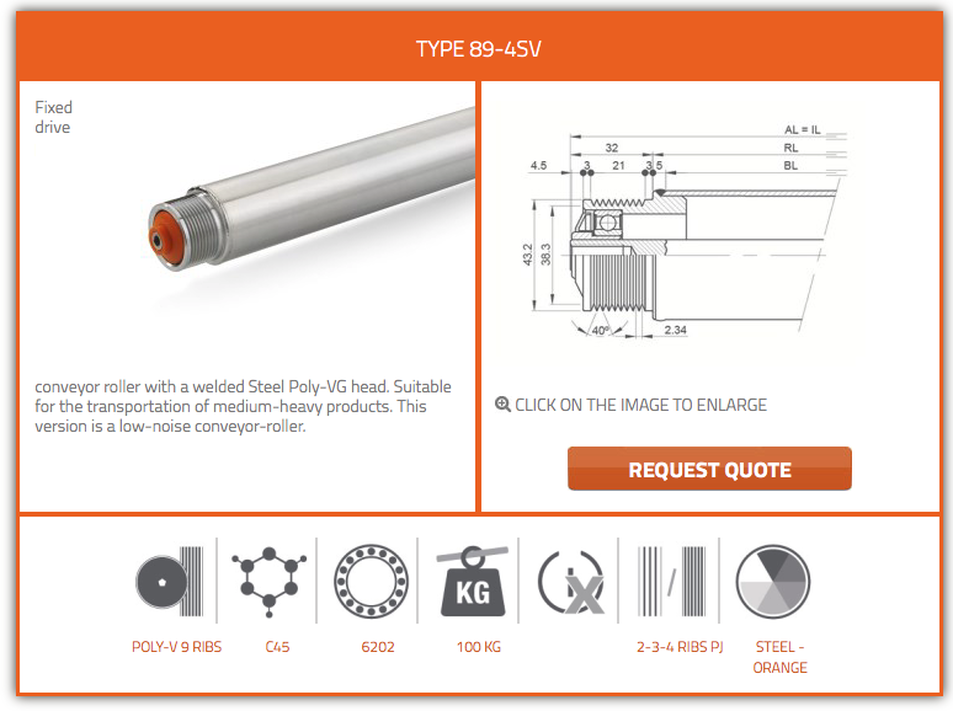

Type 89-4SV

Fixed drive conveyor roller with a welded Steel Poly-VG head. Suitable for the transportation of medium-heavy products. This version is a low-noise conveyor-roller

Fixed drive conveyor roller with a welded Steel Poly-VG head. Suitable for the transportation of medium-heavy products. This version is a low-noise conveyor-roller