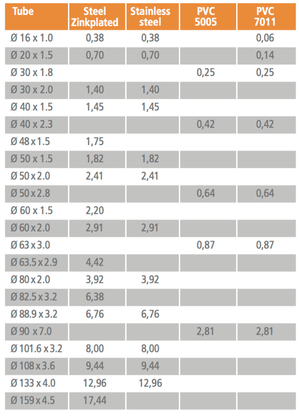

Tube.

|

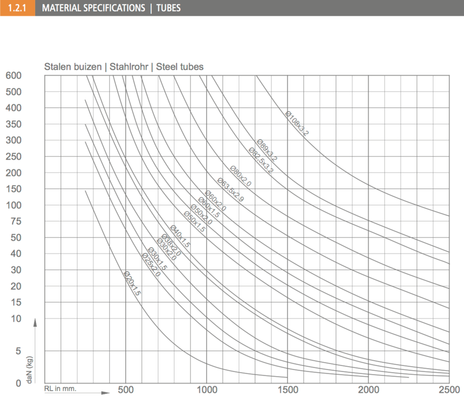

Load Diagram for Steel Tubes.

|

Tube Types

Steel Tubes

Material :welded steel precision tube made from hot-band steel, with/without weld seam filed away

Tolerance :according to DIN:2394

Quality :St:37.2 according to DIN:1710

Straightness :according to manufacturer approx 0.25% of the measured length

Note :special seamless tube is not supplied according to previous standards

Stainless Steel Tubes

Material :welded stainless steel precision tube (AISI 304)

Tolerance :according to DIN 2463 D2/T3

EUR material code number :1.4301

Straightness :according to manufacturer, approx 0.25% of the measured length

Steel Tube Galvanisation

Galvanisation Method :electrolytic

Zinc Layer :for indoor use 5 to 8 um, for outdoor use 12 to 15 um (on request)

Note galvanisation takes place after the tube has been worked, due to the quality requirements.

Steel Tube fitted with PVC or Rubber covering

The PVC or rubber covering is glued onto a sanded tube. The seam will be sealed closed where possible. The purpose of the covering is to protect the product to be transported against damage, to achieve more grip or to prevent inappropriate materials from sticking to the roller. There are lots of sorts of PVC and rubber coverings, each with different characteristics. We will be glad to advise you and help find the best possible solutions for your particular situation.

Steel Tube fitted with PVC hose

The PVC hose os blown around a tube with compressed air. The aim is mostly to protect the product to be transported against damage, to achieve more grip for transporting the product or to prevent inappropriate materials from sticking to the roller,

Material :soft PVC, hardness +/- 70 shore

Material Thickness :standard stock 3 or 5 mm

Temperature range :- 30'c to 70'c

Resistance to weathering :good

Resistance to UV :fair

Colour :Grey

Tube Diameter :deliverable in 40mm, 50mm , 60mm and 80mm dia

Powered Coated Steel Tube

In powder coating a polyester coating is applied to the tube ny ,eats of electrostatic charge. The whole object is the heated to 200'c in a curing oven, causing the powder particles to met and flow together into a single homogenous covering layer. This is done to prevent rusting.

Characteristics :impact and scratch resistant, long-lasting, easy to clean and environ environmentally friendly.

Layer Thickness :from 60 to 150 um

Colour :standard is mid grey, but can also be delivered in all other RAL colours

Temerpature Range :-10'c to 70'c without risk of discolouration (short periods unto 150'c)

Resistance to weathering :good

Resistance tp UV :excellent

Outdoor Use :for outdoorr configurations, we recommend two layers or a galvanised underlayer.

Rilsan-coated Steel Tube

Risen coating is the application of a layer of Super polyamide 11 on a tube that has been sanded and brought to a high temperature. This creates a tough, flexible, impact resistant, hardwiring and corrosion resistant layer. Risen coatings are used primarily when the roller is to come into contact with foodstuffs and drinking water.

Layer Thickness :between 300 and 400 um

Colour : MAC 5161 (mid grey)

Temperature Range :-65'c to 100'c (short periods unto 140'c)

Teflon-Coated Steel Tube

Teflon coating is the application of a covering layer of fluorocarbon on a finely sanded steel tube. Depending on the end use, this can be based on PTFE, FEP or PFA. The result is a layer that very little sticks too and that is moreover comically never enough inert. Fluorocarbon coverings are primarily used for "non-stick" and chemically resistant coverings. They are used in the food, tobacco, pharmaceutical and chemical industries.

Layer Thickness :at least 35 um

Colour :normally black

Temperature Range :-50'c to 280'c

Steel Tubes

Material :welded steel precision tube made from hot-band steel, with/without weld seam filed away

Tolerance :according to DIN:2394

Quality :St:37.2 according to DIN:1710

Straightness :according to manufacturer approx 0.25% of the measured length

Note :special seamless tube is not supplied according to previous standards

Stainless Steel Tubes

Material :welded stainless steel precision tube (AISI 304)

Tolerance :according to DIN 2463 D2/T3

EUR material code number :1.4301

Straightness :according to manufacturer, approx 0.25% of the measured length

Steel Tube Galvanisation

Galvanisation Method :electrolytic

Zinc Layer :for indoor use 5 to 8 um, for outdoor use 12 to 15 um (on request)

Note galvanisation takes place after the tube has been worked, due to the quality requirements.

Steel Tube fitted with PVC or Rubber covering

The PVC or rubber covering is glued onto a sanded tube. The seam will be sealed closed where possible. The purpose of the covering is to protect the product to be transported against damage, to achieve more grip or to prevent inappropriate materials from sticking to the roller. There are lots of sorts of PVC and rubber coverings, each with different characteristics. We will be glad to advise you and help find the best possible solutions for your particular situation.

Steel Tube fitted with PVC hose

The PVC hose os blown around a tube with compressed air. The aim is mostly to protect the product to be transported against damage, to achieve more grip for transporting the product or to prevent inappropriate materials from sticking to the roller,

Material :soft PVC, hardness +/- 70 shore

Material Thickness :standard stock 3 or 5 mm

Temperature range :- 30'c to 70'c

Resistance to weathering :good

Resistance to UV :fair

Colour :Grey

Tube Diameter :deliverable in 40mm, 50mm , 60mm and 80mm dia

Powered Coated Steel Tube

In powder coating a polyester coating is applied to the tube ny ,eats of electrostatic charge. The whole object is the heated to 200'c in a curing oven, causing the powder particles to met and flow together into a single homogenous covering layer. This is done to prevent rusting.

Characteristics :impact and scratch resistant, long-lasting, easy to clean and environ environmentally friendly.

Layer Thickness :from 60 to 150 um

Colour :standard is mid grey, but can also be delivered in all other RAL colours

Temerpature Range :-10'c to 70'c without risk of discolouration (short periods unto 150'c)

Resistance to weathering :good

Resistance tp UV :excellent

Outdoor Use :for outdoorr configurations, we recommend two layers or a galvanised underlayer.

Rilsan-coated Steel Tube

Risen coating is the application of a layer of Super polyamide 11 on a tube that has been sanded and brought to a high temperature. This creates a tough, flexible, impact resistant, hardwiring and corrosion resistant layer. Risen coatings are used primarily when the roller is to come into contact with foodstuffs and drinking water.

Layer Thickness :between 300 and 400 um

Colour : MAC 5161 (mid grey)

Temperature Range :-65'c to 100'c (short periods unto 140'c)

Teflon-Coated Steel Tube

Teflon coating is the application of a covering layer of fluorocarbon on a finely sanded steel tube. Depending on the end use, this can be based on PTFE, FEP or PFA. The result is a layer that very little sticks too and that is moreover comically never enough inert. Fluorocarbon coverings are primarily used for "non-stick" and chemically resistant coverings. They are used in the food, tobacco, pharmaceutical and chemical industries.

Layer Thickness :at least 35 um

Colour :normally black

Temperature Range :-50'c to 280'c

|

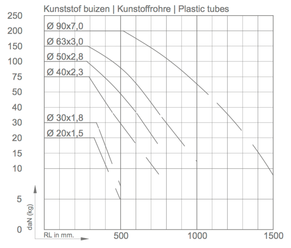

Load diagram for Plastic Tubes

|